Our Process

OUR PROCESS

The Journey of a SeaGods Wetsuit

At SeaGods Wetsuit, we don’t just craft wetsuits — we craft experiences. Every product reflects our dedication to quality, comfort, and individuality. From the first consultation to the final stitch, your wetsuit goes through a meticulous journey handled by skilled professionals using advanced techniques and premium materials. Here’s how we turn your ideas into reality.

STEP 1

Customer Service & Measurement

Your journey begins with our friendly customer service team, who help you choose from a wide range of designs, colors, and logo options — including your personal branding or one of our signature SeaGods logos.

Once the design is finalized, we take your measurements or help you select a standard size (XS to XXXL). This ensures your wetsuit fits comfortably and performs flawlessly. Every detail is recorded and passed on to our patron team for blueprinting.

STEP 2

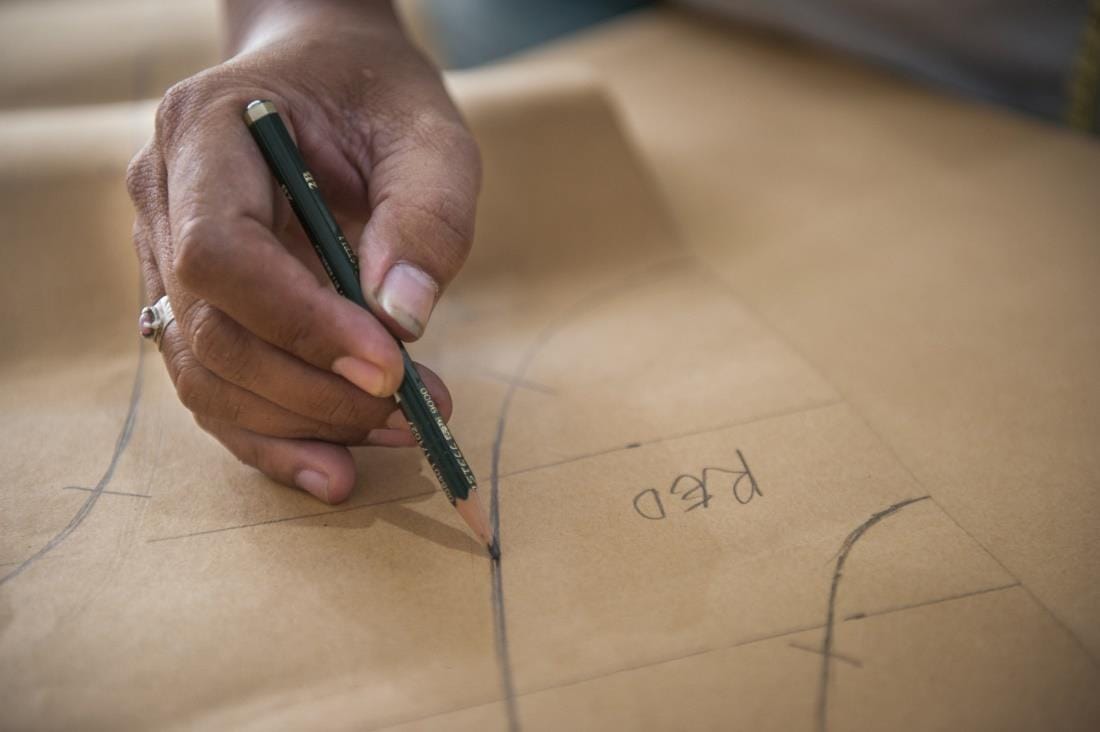

Patron / Blueprint Design

At our Patron Station, expert designers turn your measurements into precise digital blueprints. Every seam, curve, and cut line is calculated for performance, style, and comfort. This stage transforms your vision into a clear technical plan that guides the entire production process — ensuring that every wetsuit is as unique as its wearer.

STEP 3

Cutting with Precision

Our skilled cutters use high-grade tools to shape neoprene and Likra materials based on your blueprint. Precision is everything — even the smallest misalignment can impact comfort and function. Each cut is carefully inspected to meet our quality standards before moving to the next phase.

STEP 4

Personal Branding

Time to make it yours. Whether you’ve chosen a SeaGods logo or your own design, we bring it to life with high-precision printing. Logos are sharp, vibrant, and made to last — adding personality and pride to every wetsuit. This step isn’t just branding — it’s identity.

STEP 5

Triple Strength Gluing

We apply our advanced Triple Gluing technique to every seam — a method specially developed to work with neoprene’s microbubble structure. By gluing three times, we ensure even adhesion, maximum durability, and minimal risk of leaks. This process enhances both performance and longevity underwater.

STEP 6

Stitched to Perfection

At the Sewing Station, our artisans bring your wetsuit to life. Each seam is carefully stitched using specialized techniques and reinforced threads. This step ensures structural integrity, tear resistance, and a smooth finish — without sacrificing comfort or flexibility.

STEP 7

Extra Strength, Seam by Seam

We add an additional layer of durability with the stamping process. This reinforces the seams at high-stress areas to reduce wear and increase longevity. The result? A wetsuit that can handle every wave, dive, and movement — time after time.

STEP 8

Final Check, Guaranteed Quality

At our CO Station, each wetsuit undergoes rigorous inspection. Our QC team checks every seam, stitch, logo, and cut to ensure nothing leaves our factory unless it’s perfect. Once approved, we carefully package the wetsuit for delivery — ready to accompany you on your next water adventure.

More Than Just a Wetsuit

From raw material to final inspection, every SeaGods wetsuit tells a story — of craftsmanship, performance, and personal expression. Whether you’re a pro athlete or weekend diver, our process ensures you receive a wetsuit that fits your body and your lifestyle perfectly.